Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

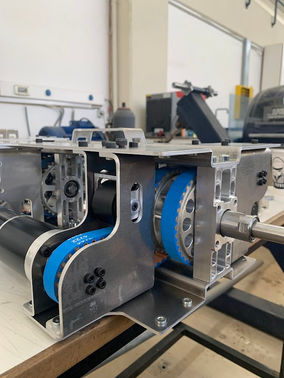

Quadruped Robot Laelaps III

Project type

MEng Diploma Thesis

Role

Diploma Student

Research Team

Date

November 2024

Diploma Thesis

Diploma Thesis Presentation

Assembly Video

This project focused on the redesign and optimization of the mechanical foundation and drivetrain of Laelaps, a quadruped robot developed by the Legged Robots Team at the Control Systems Laboratory (CSL) of NTUA for dynamic locomotion and mobility research.

I led the mechanical design, analysis, and fabrication of both the chassis and transmission subsystems, targeting improvements in structural integrity, power transmission capability, and mass reduction.

Key Achievements:

• Lightweight Chassis Redesign

Reduced overall mass by 18% (from 39.3 kg to 32 kg), significantly improving agility and energy efficiency. The redesign also eliminated actuator–leg collisions, enabling the robot’s full range of motion.

• High-Torque Transmission Optimization

Re-engineered the leg transmission system, more than doubling output torque (hip: 38.6 Nm → 80.8 Nm; knee: 40.4 Nm → 80.8 Nm), greatly enhancing load capacity and control precision.

• Full-Cycle Prototyping

Managed the complete prototyping workflow — from 3D CAD modeling and CAM programming to CNC machining and assembly — integrating both in-house and outsourced manufacturing processes.

• Precision Manufacturing

CNC-machined 56 components across 10 unique part designs in-house, maintaining ±0.01 mm tolerances for precise assembly and consistent performance.

All sheet metal components were outsourced to external fabricators, with design and manufacturing specifications provided to ensure dimensional and functional accuracy.

• Quality Control

Performed dimensional inspections using calipers and micrometers to ensure accuracy and mechanical reliability across the chassis and transmission assemblies.